Introduction: Navigating Pressure Sensing Challenges

Imagine an oil rig facing unexpected pressure spikes—these situations can lead to catastrophic failures, affecting safety and productivity. With the primary focus on efficiency, the hammer union pressure sensor is a critical component for monitoring these fluctuations. According to industry studies, over 60% of pressure-related failures can be attributed to inadequate monitoring solutions. Why do failures always occur during critical operations? This is where effective pressure sensing technology plays a crucial role.

Body: Technical Breakdown of Pressure Sensing Solutions

Flaws of Traditional Solutions

Many conventional pressure sensing devices are often plagued with issues like response lag and inaccuracies. These sensors might not withstand extreme conditions, leading to erroneous readings that could compromise operations. In environments where split-second decisions matter, such flaws become unacceptable—resulting in financial losses and safety risks.

Principles Behind New Technologies

Advancements in sensor technology are here to address these shortcomings. Modern hammer union pressure sensors leverage advanced materials and design principles—such as enhanced biocompatibility and real-time data processing. These innovations ensure that sensors can function optimally in harsh environments, ultimately leading to better reliability and accuracy in monitoring.

User Benefits Quantified

Utilizing state-of-the-art hammer union pressure sensors has demonstrated significant improvements in operational efficiency. Companies report up to a 30% decrease in downtime and a remarkable enhancement in safety protocols due to real-time monitoring capabilities. Look, it’s simpler than you think; the integration of these sensors into your existing systems can yield substantial benefits without a complete overhaul.

Conclusion: The Path to Informed Choices

When selecting an appropriate pressure sensing solution, always verify these 3 metrics: ① accuracy of readings, ② environmental resilience, and ③ response time. Understanding these factors will guide you to the best option for your specific needs, ensuring a secure and efficient operational environment.

Expanding on Hydraulic Pressure Sensors

The hydraulic pressure sensor is integral to various applications, enabling precise control over hydraulic systems. Its design factors in elements such as temperature ranges and fluid compatibility, ensuring optimal performance. However, traditional gauges can be limited by their resolution and operational lifespan. Advanced models minimize these drawbacks by incorporating durable materials and real-time data analytics, facilitating prompt decision-making—an essential feature in high-stakes environments.

Diving Deeper into Hammer Union Pressure Transducers

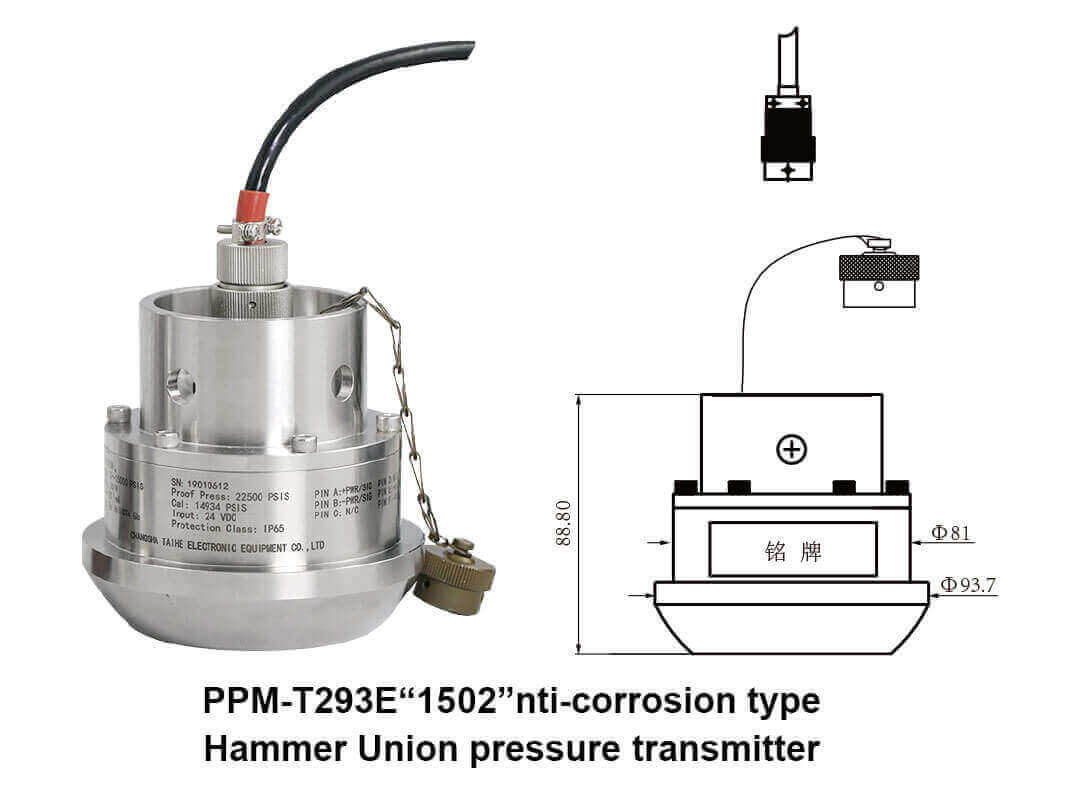

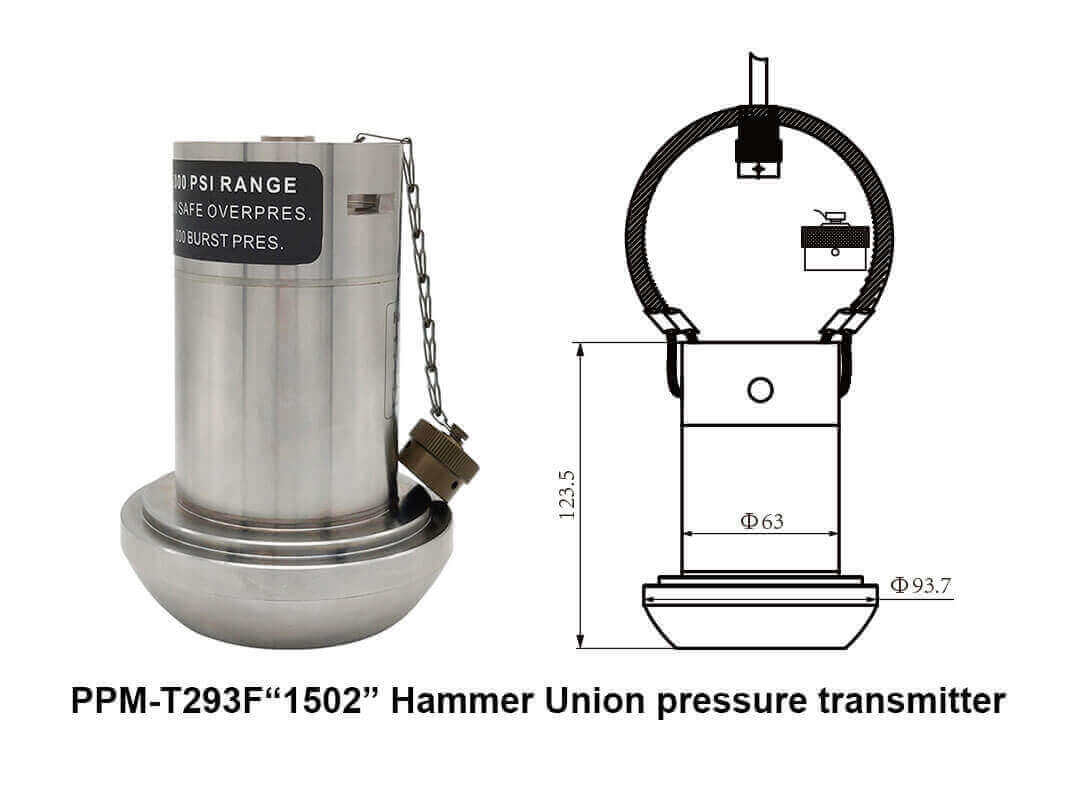

In the realm of industrial applications, the hammer union pressure transducer stands out as a pioneering solution. These transducers excel in providing accurate pressure measurements across diverse conditions, enhancing system reliability. By utilizing advanced sensing technology, they offer quicker response times and better accuracy than older models. This effectiveness translates directly to reduced operational costs and improved safety, key factors for businesses that prioritize optimal performance.

Summary and Brand Recommendation

Enhanced pressure monitoring through sensors like the hammer union pressure sensor offers significant operational advantages, while hydraulic and pressure transducers ensure precision in demanding environments. As pressures to improve safety and efficiency grow, so too does the need for reliable sensing technology. Brands like CSSPM Sensor emerge as industry leaders, ensuring supply advantages paired with cutting-edge technology—an asset for any organization aiming to thrive in today’s challenging industrial landscape.